UmproTech

UmproTech 510H | 5′x10′ High-Power Fiber Laser Cutter – Gen 4 NEW

No se pudo cargar la disponibilidad de retiro

🇺🇸 UmproTech 510H — 5′×10′ Industrial Fiber Laser Cutter

Full-format 5′×10′ bed • LS6000M AI control • U.S. setup, training & support

Key Specifications

- Cutting Bed

- 5′ × 10′ full format (1525 × 3050 mm)

- Laser Power

- 3–30 kW fiber source (configurable)

- Controller

- LS6000M AI — nesting, pierce libraries, auto-height

- Traverse Speed

- Up to ~100–140 m/min (application dependent)

- Positioning Accuracy

- ±0.001–0.002″ (±0.03–0.05 mm) typical

- Frame

- Heavy-duty welded steel, anti-vibration

- Fully enclosed protective housing

- Automatic dual-pallet shuttle changer

See more fiber laser cutters, laser cleaners, and laser welders.

Share

High-Power Fiber Laser Cutter | 5×10 Industrial Systems – UmproTech USA

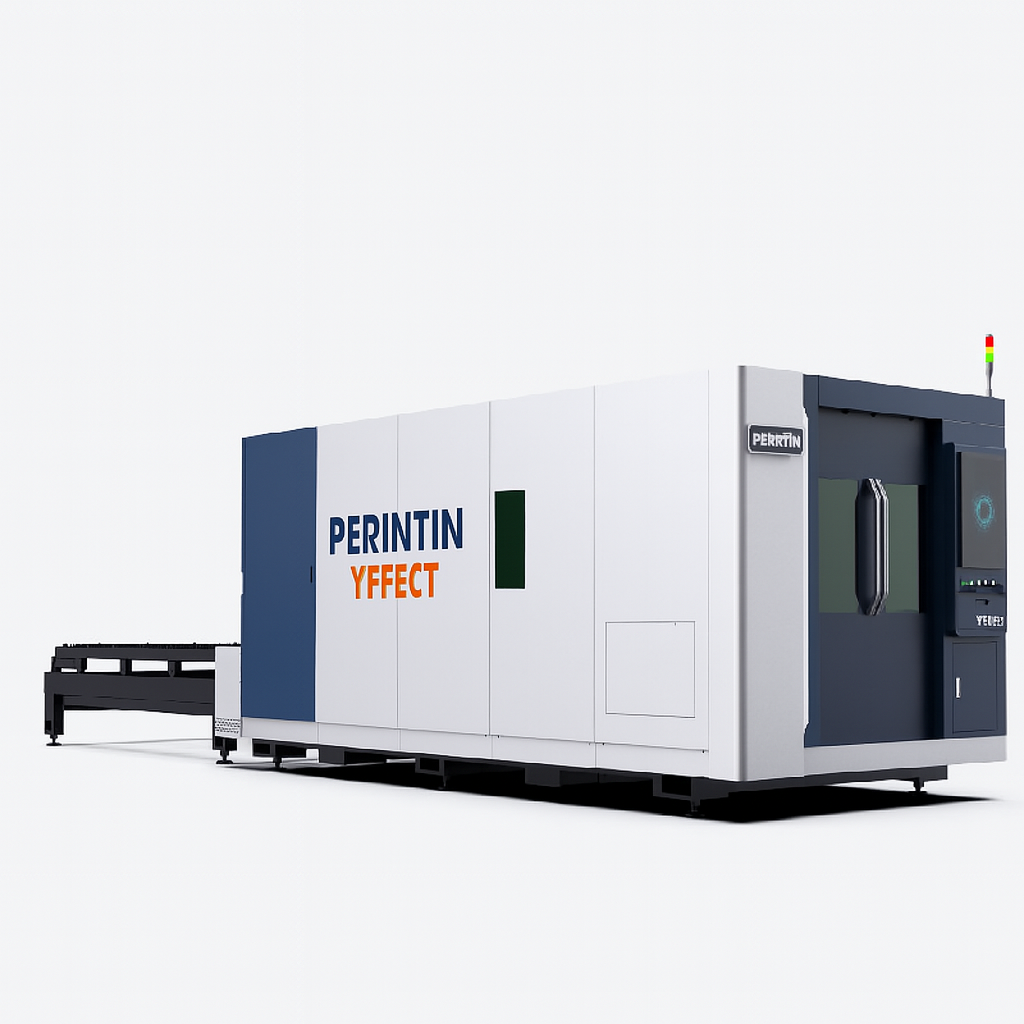

🇺🇸 UmproTech 510H — Fourth-Generation High-Power Fiber Laser Cutter (5′×10′)

Engineered for Heavy-Duty Production • 6–30 kW • Fully Enclosed • Dual Auto-Exchange Tables

The UmproTech 510H Series sets a new standard in industrial metal fabrication. Built for uptime, precision, and safety, the 510H combines an enclosed Class-4 laser enclosure with fast dual shuttle tables (typical exchange ≈20 s) to keep your operators protected and your throughput high.

Available power from 6 kW to 30 kW covers stainless production and thick-plate carbon steel. The thermally isolated bed and aerospace-grade gantry preserve accuracy during continuous high-power work.

Certifications & Compliance

Compliance scope depends on configuration and market. Ask our team for the exact certificate set for your build.

Key Technical Specifications

| Model | 510H | 6120H | 8025H | 12025H | 12528H |

|---|---|---|---|---|---|

| Laser Power | 6–30 kW | 6–30 kW | 6–30 kW | 6–30 kW | 6–30 kW |

| Cutting Area | 121″ × 60″ | 238″ × 80″ | 317″ × 100″ | 474″ × 100″ | 494″ × 111″ |

| Position Accuracy | ±0.05 mm | ±0.05 mm | ±0.05 mm | ±0.05 mm | ±0.05 mm |

| Repeatability | ±0.02 mm | ±0.02 mm | ±0.02 mm | ±0.02 mm | ±0.02 mm |

| Max Motion Speed | Up to 590 in/min* | Up to 590 in/min* | Up to 590 in/min* | Up to 554 in/min* | Up to 590 in/min* |

| Max Table Load | 3,000 kg | 6,000 kg | 8,000 kg | 14,000 kg | 16,000 kg |

*Application-dependent; actual speeds vary by material, thickness, gas, nozzle, path strategy.

Core Features

🏗️ Heavy-Duty, Thermally Isolated Bed

Thick-walled steel, stress-relieved; insulated hollow bed minimizes heat transfer and preserves geometry over years of high-power cutting.

🌀 Smart Zonal Extraction

Zones follow the cutting head to keep smoke down and optics cleaner, improving air quality and reducing maintenance.

🔥 Graphite & Copper Shielding (≥8 kW)

Protects the bed from reflected energy and slag on thick-plate jobs.

✈️ Aerospace-Grade Gantry

Ribbed aluminum for high stiffness/low mass → fast response and clean edge quality.

🧠 Control — UmproTech LS6000M

- Presets & cut libraries

- Auto-nesting & path optimization

- Self-diagnostics & maintenance prompts

🪙 Gas & Nozzles

O₂ / N₂ / Air with validated recipes for steel, stainless, aluminum.

Typical Cutting Capability (Guidance)

Carbon Steel (O₂/N₂)

- 6 kW: ~20 mm

- 12 kW: ~30 mm

- 20–30 kW: ~40 mm+

Depends on edge spec & gas purity.

Stainless (N₂)

- 6 kW: ~12–14 mm

- 12 kW: ~20–25 mm

- 20–30 kW: ~30 mm

Aluminum (N₂/Air)

- 6 kW: ~10–12 mm

- 12 kW: ~16–20 mm

- 20–30 kW: ~25–30 mm

Utilities, Footprint & Safety

⚡ Power & Air

- 480 V 3-phase (other on request)

- Clean, dry compressed air

- Chiller included, sized to kW

📐 Space & Weight

- 5′×10′ enclosure with dual shuttles

- Allow service aisles; rigging per site

🛡️ Safety & Compliance

- Enclosed Class-4 with interlocks

- Practices aligned with ANSI Z136.1

- Local code support available

UmproTech 5-Star Support Promise

⏱️ 24/7 Response

Initial response ~10 min, most software issues ~1 hour, U.S. engineer dispatch ~1 business day.

👨🏭 Install & Training

On-site installation and operator training. We cover travel; you provide lodging/meals.

🛡️ Warranty

2-year machine & source; non-consumable parts replaced free during warranty.

💎 Lifetime Care

Demos, lifetime software updates, self-diagnostics, optional extended coverage.

FAQ

What gas setup do I need for 12 kW+?

N₂ for stainless/aluminum finish, O₂ for carbon steel thickness, clean dry air for certain cost-down jobs. We’ll size regulators, nozzles, filters.

Can you retrofit our extraction and electrical?

Yes. We can integrate with existing utilities or deliver a turnkey package (chiller, filtration, cabinet, grounding, interlocks).

What’s included in commissioning?

Assembly, calibration, cut-library setup for your materials, safety checks, and operator training.

Ready to boost your production?

Request a Custom Quote Trade-In / Upgrade ProgramTalk to our U.S. team: +1 (872) 268-5842 • info@umprotech.com

UmproTech Inc. — American-Owned • Precision Metalworking Machinery • Built for Results